4D printing technology revolutionizes the field

The invention of a 4D printer would introduce a new dimension in the printed objects: time. Photo Credit: Google Images.

By Rhett Maiorana, Contributing Writer

3D printing technology is dramatically revolutionizing many areas of society and its usage is rising fast. But there is something even better around the corner: 4D printing.

Now, the printing we do at the library, that’s 2D. Those machines can only take in to account length and width. 3D printing creates objects, which require length, width, and height.

3D printing is relatively recent and its benefits still have not been completely realized. The byproducts of 3D printing include the retainers we’re all supposed to wear every night, custom-made prosthetic limbs, and eventually human organs.

However, 3D printing can be used for criminal purposes as well. Firearms can and have been made with 3D printers. Also, keys can be manufactured to fit a desired lock. If 3D printers were as commonplace as laptop computers, DPS’s job would be much more difficult.

4D printing still makes three-dimensional objects, but it incorporates time. Instead of creating a fixed object, the item changes under different circumstances. For instance, imagine a 4D printed mug that prevented burns by growing thicker after hot coffee was poured into it. 4D printed items are physical materials that are programmed to act a certain way.

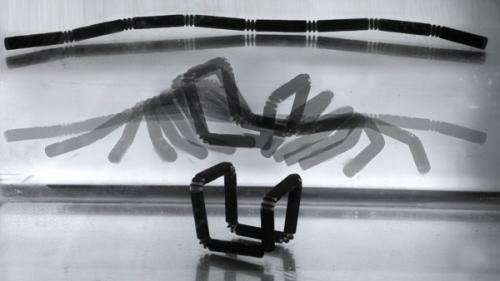

Before, only computers could run programs, but that is changing. A lab at MIT produced a string that, once placed in water, assembled itself into a cube shape.

This technology could be used to perform tremendously useful tasks. Pipes and plumbing could not only expand and contract to increase or decrease flow of water based on demand, but they could undulate just the way your esophagus does to move the water it without using expensive pumps. The clothes soldiers wear could be coated with this material. Then, their gear’s color, permeability and hardness would automatically adjust based on the surroundings.

This seems like the talk of a science fiction novel, but it’s the reality of the future and it looks exciting!